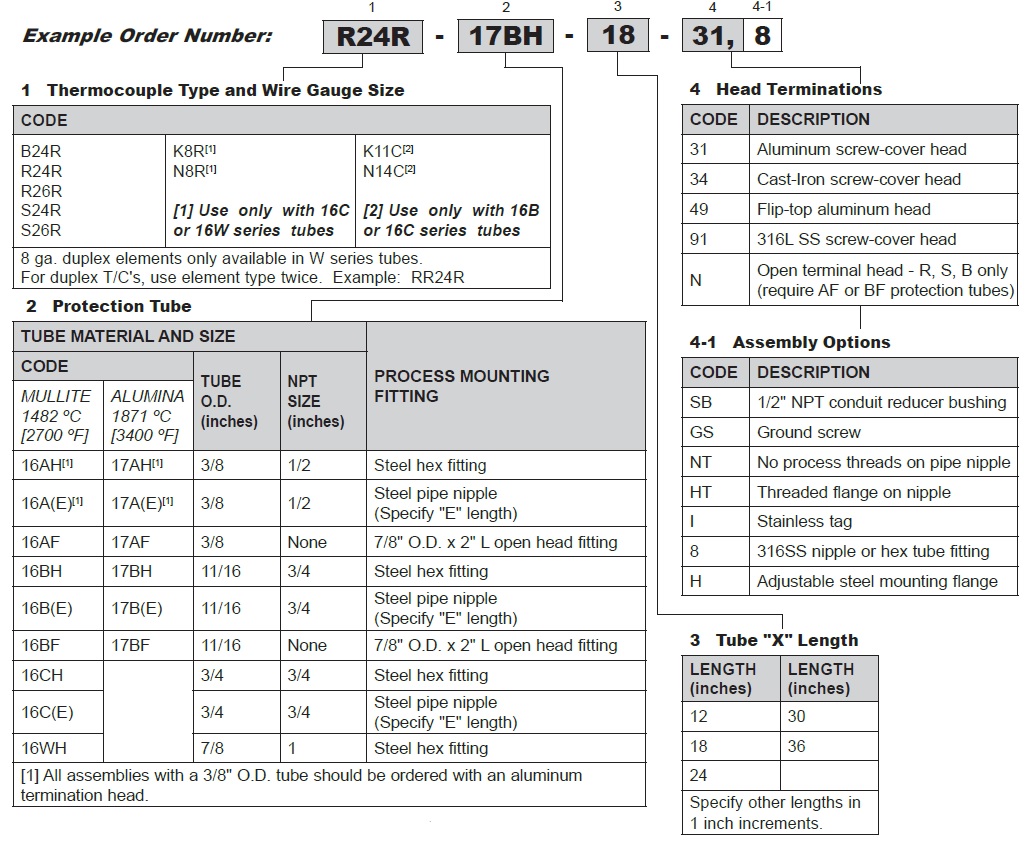

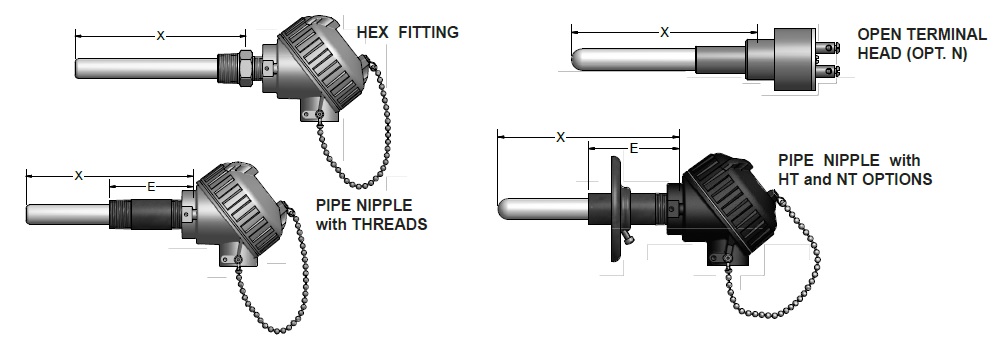

We supply a variety of thermocouple assemblies with ceramic protection tubes.

The straight noble- and base-metal thermocouple assemblies, with Series 16 mullite and Series 17 alumina protection tubes, illustrated on this catalog page are those most commonly used in high temperature process heating applications. These assemblies are available with a variety of process mounting fittings and assembly options as listed below. Special construction designs are also available.

Pre-Heating Ceramic Protection Tubes

The following information applies to both the Mullite and Alumina versions of the ceramic protection tubes.

Installation into a running process

Insert the ceramic protection tube into a running process at the rate of 1” per hour per 100°C to prevent thermal shock and possible breakage. For example, if your furnace is operating at 600°C, then you should take six hours to insert the ceramic tube into the furnace.

Installation into a cold process (startup)

If your ceramic tube is already installed in a cold process, the heat should increase at a rate of no more than 100°C per hour to minimize thermal shock to the tube.

These are general guidelines only. If you have specific questions regarding your particular process, please contact us for technical assistance.

Please call us at (800) 446-4316 or contact us here for a quote or for thermocouple selection assistance.