We also supply RTDs manufactured by Pyromation. We will soon be updating our website with specification data for the following types of RTDs.

General Purpose RTDs

- Single and Duplex Element RTDs

- Single and Duplex Element RTDs

- Water-Tight RTD Assemblies w/Optional Series 450 Temperature Transmitters

- M12 Molded and Field Wireable Cables

Sensors with Connection Heads

- Fixed Sheath RTD Assemblies w/Connection Heads

- Spring-Loaded RTD/Thermowell Assemblies w/Connection Heads

- Spring Loaded Replacement RTD Elements

- Fixed Sheath RTD Assemblies w/Miniature Connection Heads

Food, Dairy, and Pharmaceutical

- Water-Tight CIP RTD Assemblies w/Optional Series 450 Integral Transmitters

- CIP Sanitary-Connected RTDs

- RTDs w/CIP Sanitary-Connected Wells

- Miniature Sanitary CIP RTD Sensors

- Thermometer Replacement

- Weld-In RTD Assemblies

Plastic

- General Purpose Plastic Industry RTDs

- Spring- or Armor-Adjustable Immersion RTDs

- Melt Bolt

- Threaded Nozzle

- Ring

- Flexible RTD Extensions

Special Purpose

- FEP-Coated RTD Assemblies

- Heat Tracing Temperature Sensors

- RTD Averaging Sensor

- Thermostat Temperature Sensors

- Variable Length RTD Sensors

Explosion Proof

- Hazardous Location Explosion-Proof Approved Fixed-Element Assemblies

- Hazardous Location Explosion-Proof Approved Assemblies w/Thermowells

- Hazardous Location Explosion-Proof Approved, Spring-Loaded Assemblies

Bearing Sensors

- Miniature Temperature Sensors

Specific Application

- Non-Intrusive Tank Sensors

Here is some general information regarding RTD technology.

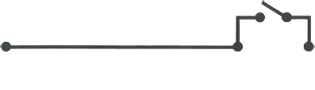

Resistance thermometers

Resistance thermometers, also called resistance temperature detectors (‘RTD’s), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it is often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel or copper. The material has a predictable change in resistance as the temperature changes; it is this predictable change that is used to determine temperature.

They are slowly replacing the use of thermocouples in many industrial applications below 600 °C, due to higher accuracy and repeatability.

Our purpose is to correctly identify needed items and have them delivered on time at maximum value. We routinely handle this by direct contact with our customers, maintenance operations, production, engineering and/or purchasing. If in doubt as to our scope of supply, please contact us via our online form or call us at (800) 446-4316.