M&W Controls supplies a wide variety of temperature measurement and control equipment. We are a distributor for Pyromation, and have a distributorship relationship with other suppliers as well.

We will soon be updating our website with catalog information for many of the types of temperature instrumentation we supply, including:

Temperature Instrumentation

Here is some general information concerning temperature measurement technologies that may be useful in determining what method best meets the needs of your application.

Contact sensing brings the sensor in physical contact with a substance or object. It can be used with solids, liquids or gases. Non-contact (infrared) temperature sensing reads temperature by intercepting a portion of the infrared energy emitted by an object or substance, and detecting its intensity. Non-contact is used to sense the temperature of solids and liquids. Non-contact cannot be used on gases due to their transparent nature.

Contact Temperature Sensor Types and Comparisons

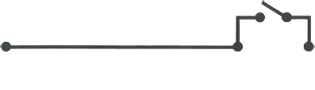

Contact sensors, aside from capillary/bulb thermometers and bi-metal sensors, use varying voltage signals or resistance values.

Voltage Signals

Thermocouple sensors generate varying voltage signals. The different metal and alloy combinations in the thermocouple’s legs produce a predictable voltage for a given temperature.

Resistance Values

Resistance temperature detectors (RTDs) generate varying resistance values. RTDs as a class are divided into two types:

- Resistance wire RTD

- Thermistor (thermally sensitive transistor)

RTDs work by producing a predictable resistance at a given temperature. Resistance wire RTDs (generally platinum) have a positive coefficient by increasing resistance with temperature increase. Thermistors are generally negative coefficient by decreasing resistance with temperature increase. Each of these three contact sensor types (RTDs, thermocouples, and thermistors) have advantages and disadvantages depending on application, desired response time and accuracy. A presentation of general benefits can help determine the most suitable contact sensor type.

Thermocouple Advantages

Extremely high temperatures: Noble metal thermocouples may be rated as high as 1700°C (3100°F).

Ruggedness: The thermocouples’ inherent simplicity enables them to withstand shock and vibration.

Small size/fast response: Thermocouples with exposed or grounded junctions offer nearly immediate response to temperature changes.

RTD Advantages

- Wide temperature range: Watlow platinum sensors cover temperatures from -200 to 650°C (-328 to 1200°F).

- Repeatability and stability: The platinum resistance RTD is the primary interpolation instrument used by the National Bureau of Standards from -260 to 630°C (-436 to 1135°F). Precision RTDs can be manufactured with stability of 0.0025°C per year. Industrial models typically drift less than 0.1°C per year.

- High output: The current drop across an RTD provides a much larger signal than thermocouple voltage output.

- Linearity: Platinum and copper element RTDs follow a more linear curve than thermocouples or most thermistors.

- System wiring cost: Unlike a thermocouple, an RTD uses ordinary copper leads for extension wires and requires no cold junction compensation.

- Area sensing: Point measurements, while often desirable, may cause errors. An RTD element can be spread over a large area, improving control with area averaging, a technique impractical with thermocouples.

Thermistor Advantages

Due to wide performance and cost variations among thermistors, generalized advantages and disadvantages may not always apply. Common benefits include:

- Low sensor cost: Most thermistors in their basic form cost much less than RTDs. When assembled in protective sheaths the price difference narrows.

- High resistance: Base resistance may be several thousand ohms. This provides a larger signal change compared to resistance wire RTDs with the same measuring current, negating leadwire resistance problems.

- Interchangeability: Many newer thermistor models are trimmed to very tight tolerances over limited temperature ranges.

- Point sensing: Thermistor beads may be pinhead size for point sensing.

Contact Sensor Conclusions

- Thermocouples are best suited to high temperatures, environmental extremes, or applications requiring microscopic size sensors.

- RTDs are best for most industrial measurements over a wide temperature range, especially when sensor stability is essential for proper control.

- Thermistors are best for low cost applications over limited temperature ranges.