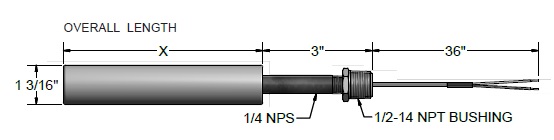

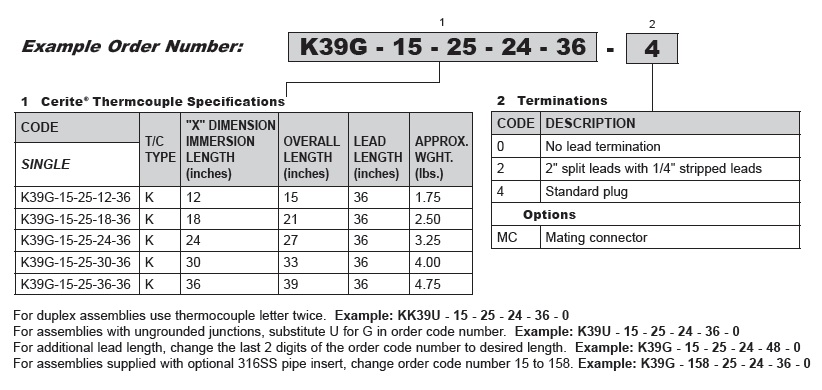

Cerite® III thermocouples are provided with a protection tube, integral thermocouple element with 36″ of high temperature 704 ºC [1300 °F] fiberglass leads, and a 1/2″ NPT steel male face bushing for use in mounting. They are constructed by casting a phosphate bonded refractory material containing 85% alumina, 4% silica, and other trace elements around a 1/4″ NPT steel pipe, containing an integral stainless steel sheathed magnesium oxide (MgO) insulated thermocouple element. The cast refractory material was developed for use in molten non-ferrous metals, specifically molten aluminum and zinc. It has excellent non-wetting properties, allowing easy slag removal, and the small diameter provides fast thermal response to process temperature changes. These assemblies provide good resistance to thermal shock and mechanical breakage. The refractory material is rated at 1538 ºC [2800 ºF] however, its use as a Cerite® III thermocouple assembly is generally limited to 815 °C [1500 °F] maximum. Protection tube pre-heating and slow immersion into the process is recommended.

Please call us at (800) 446-4316 or contact us here for a quote or for thermocouple selection assistance.