Description

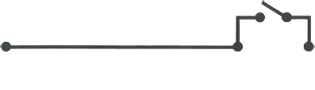

The Intempco LTX22 is a capacitance level sensor designed for modulating level control of liquids in metallic tanks. The probe is normally installed in a steam boiler, or metal tank where it is grounded through the process connection, the boiler tank forming the reference ground. It can be used in a non conductive tank if a grounding rod is provided.

The probe measures level by measuring the change in electrical capacitance as level changes in the tank. The micro-processor based electronics convert this capacitance change into a linear, highly accurate output signal. This signal may be used with one or more electronic modules to provide level control, level alarms, and/or outputs to a building management system.

The LTX22 is available with an enclosure and installed electronics or an enclosure and remotely installed electronics in a NEMA 4 box. The connection is made via coax cable. Remote electronics are a preferred choice for higher ambient temperature applications.

Features

- High pressure/temperature design for steam boilers

- Transmitter housed in rugged aluminum head or remotely

- Continuous loop powered 4-20mA operation

- Microprocessor Based

- Accuracy 1% of span for constant dielectric of material

- Non-interactive zero and span calibration

- Calibration accomplished with 4 push buttons

- High pressure 1/2″ & 3/4″ fittings available

- Ceramic clad inner stainless probe design

Application

- High pressure/temperature steam boilers

- For level control in building management

- Water and water-based liquids.

- On-site calibration required

- Not recommended where material dielectric changes

- Tank must be conducive or grounding may be required or see other Intempco level probes.

- Do not use in high vibration/shock applications

- Read “Safety Information” carefully in LTX22 instruction manual as operation in steam boilers is a very serious matter

Please call us at (800) 446-4316 or contact us here for more information on capacitance level switches, other level sensing equipment or for any other process variable control needs.